Development partner for high-tech mechatronic systems! Contact Us

Positioning Terminology

Introduction

Understanding terms such as accuracy, repeatability, resolution, and precision is crucial in the fields of precision engineering and machine design. However, these terms are often misunderstood or used interchangeably. This leads to confusion and misinterpretation, which can result in miscommunication with customers and ultimately in incorrect specifications. Clear and precise usage of these terms is essential to avoid such issues and ensure accurate communication of technical requirements.

Target and true position

The target position refers to the location to which you command a machine to move. This is represented by the center of the concentric circles. On the other hand, the true position is the actual location of the machine after it has moved. This is represented by a black dot on the concentric circles. The difference between the target position and the true position is commonly referred to as the ‘position error’ or ‘positioning error’.

Accuracy

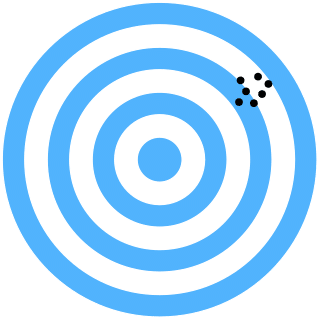

Accuracy refers to how close the true position (the actual position of a machine) is to the target position. It’s a measure of the system’s ability to hit the exact position it’s supposed to. High accuracy means the true position closely matches the target position.

Repeatability

Repeatability refers to the ability of a machine or system to return to the same position repeatedly under the same conditions. It’s a measure of consistency: when given the same command multiple times, the system should always reach the same point (or very close to it). High repeatability means that each time the machine moves to a target position, it ends up in virtually the same true position, even if that position is not exactly where it was intended to be (which would be a question of accuracy).

Accuracy vs. repeatability

Good accuracy

Good repeatability

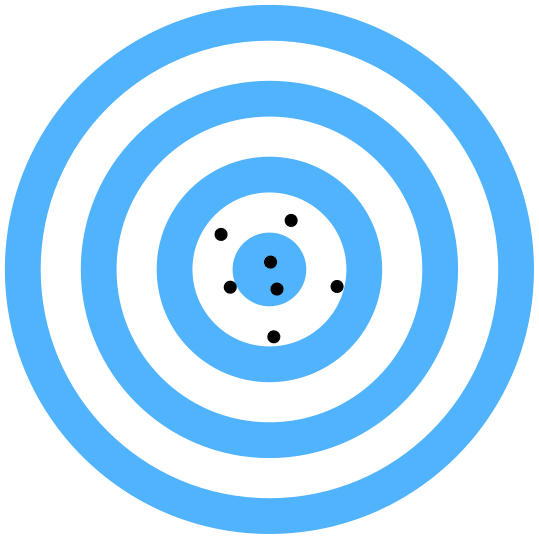

Bad accuracy

Good repeatability

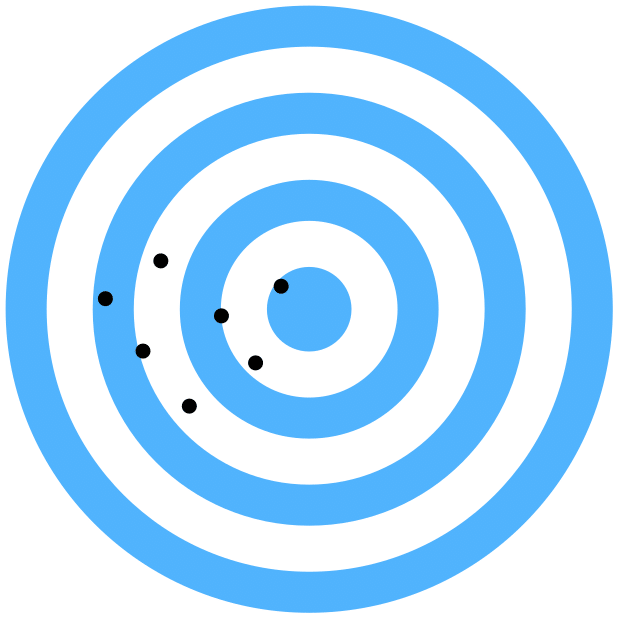

Good accuracy

Bad repeatability

Bad accuracy

Bad repeatability

Reproducibility

Reproducibility refers to the ability of a machine or system to achieve the same positioning results under different conditions. This means that if you set the same target position but under varying conditions (like different operators, machine, …), the system should consistently reach a position close to the intended target.

Unlike repeatability, which tests consistency under the same conditions, reproducibility assesses the uniformity of outcomes across different scenarios. High reproducibility indicates that a system is reliable and stable, not just in a controlled environment, but also in variable real-world situations. It’s an essential measure in ensuring that a system or process can be trusted to deliver similar results no matter the external changes.

Precision

Precision is a synonym for repeatability, i.e. is the degree to which repeated measurements under the same conditions show the same results.

Resolution

From a sensor’s point of view, resolution refers to the smallest change in position that the sensor can detect and accurately measure. Higher resolution indicates that the sensor can detect smaller positional changes. This aspect of sensor performance is also known as sensor sensitivity. On the other hand, from a machine’s perspective, resolution is defined as the smallest controlled displacement that can be executed. This is often referred to as the minimal step size or minimal incremental motion.

Error motion

Error motion refers to the unintended movements or deviations in a rotary system from its ideal rotational path. A detailed description can be found here.