Development partner for high-tech mechatronic systems! Contact Us

Flexure mechanisms

Introduction

Flexure-based mechanisms utilize flexible elements, such as leaf springs and elastic hinges, which deform under load, providing controlled motion. Unlike traditional mechanisms that rely on joints and bearings, flexure-based systems achieve movement through the elastic deformation of these flexures, ensuring backlash and friction free motion without the need for lubrication or maintenance.

Advantages

- High precision: one of the most significant advantages of flexure-based mechanisms is their ability to achieve high precision and repeatability in positioning applications. The lack of wear and backlash, common in traditional mechanisms, allows for accurate movements.

- No friction or lubrication: since there are no sliding or rolling contacts, flexure-based mechanisms operate without friction. This eliminates the need for lubrication, reducing maintenance requirements and the risk of contamination, a critical factor in clean room environments.

- Simplicity and reliability: with fewer moving parts, these mechanisms are inherently simpler and more reliable. Their design can be highly compact and integrated, enhancing the overall robustness of the system.

- Vacuum compatibility: the absence of lubrication and out-gassing materials makes flexure-based mechanisms ideal for vacuum applications.

Disadvantages

- Limited range of motion: the primary drawback of flexure-based mechanisms is their limited range of motion, confined by the elastic limits of the materials used. This makes them less suited for applications requiring large displacements.

- Complex design and manufacturing: designing flexure-based systems requires sophisticated engineering tools to accurately predict flexural behavior and stress distribution. Additionally, manufacturing these mechanisms often involves precision machining and fabrication techniques, increasing production costs.

- Material fatigue: repeated deformation can lead to material fatigue, potentially reducing the mechanism’s lifetime. Selecting appropriate materials and designing for durability are crucial considerations.

Applications

Flexure-based mechanisms find their applications in several fields where precision is paramount:

- Micro- and Nano-positioning: in semiconductor manufacturing and microscopy, they enable precise manipulation and positioning at the micro- and nano-scale.

- Optical alignment: used in telescopes, cameras, and laser systems to achieve fine adjustments in lens and mirror positions.

- Biomedical devices: for surgical tools and laboratory instruments, where precise, smooth motion is necessary.

- Aerospace: in satellite components and space telescopes, where reliability and vacuum compatibility are critical.

Case study

Micrometer-level positioning with a simple screw🔩? Yes, why not…

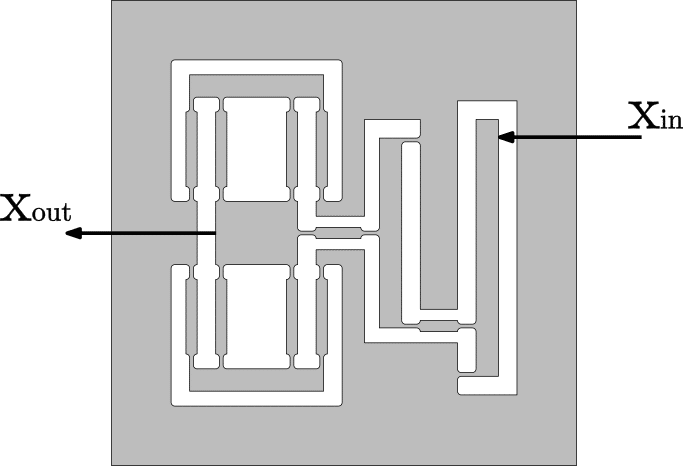

The video below shows a 3D-printed prototype of a flexure-based mechanism to validate a micrometer-level positioning concept. The compliant mechanism consists of a symmetric double parallelogram flexure and a 1:15 transmission ratio. A 1.5 mm screw displacement translates into a precise 100 micrometer movement.